CHALLENGER 2 The Challenger 2 is the first British Army tank since World War II to be designed, developed and produced exclusively by a single prime contractor, Vickers Defence Systems, with set reliability goals laid down in the fixed price contract. Challenger 2 was designed and manufactured at both Vickers sites, Barnbow Leeds and Scottswood Newcastle. The hull and automotive parts of the Challenger 2 are based upon its predecessor Challenger 1, but Challenger 2 incorporates over 150 improvements aimed at increasing reliability and maintainability. The turret of Challenger 2 is a totally new design. Armour is an uprated version of Challenger 1's Chobham armour. The Challenger 2 is the best protected tank in NATO (10) incorporating Chobham second-generation armour plating. Its NBC (nuclear, biological and chemical protection) system is capable of dealing with all known threats and, for the first time in any British tank, the crew compartment has both a heating and a cooling system. The main armament consists of a Royal Ordnance 120 mm rifled tank gun designated the L30. It also incorporates a McDonnell Douglas Helicopter Systems 7.62 mm chain gun, which is already in service in the British Army, being installed in the GKN Defence Warrior mechanized combat vehicle, and a 7.62 mm anti-aircraft machine gun. The Challenger 2's fire control system is the latest-generation digital computer from Computing Devices Company (CDC) of Canada and is an improved version of that installed in the US M1A1 Abrams tank. It also has growth capacity for future enhancement such as a Battlefield Information Control System and navigation aids. The Challenger 2 carries a crew of 4 and has a combat weight of 62.5 tonnes. It has a maximum road speed of 56 km/h and a range of 250 km cross country and 450 km on the road. The Challenger 2 (CR2) project includes the development and production of 386 CR2 Main Battle Tanks (MBTs), 22 Driver Training Tanks (DTTs), CHARM 3 ammunition and a full support package including training equipment and initial spares. Prime Contractor was Vickers Defence Systems plc. Vickers Defence Systems started work on the Challenger 2 in November 1986 as a private venture and shortly afterwards, in March 1987, made its first presentation of the vehicle to the British Ministry of Defence. In February 1988, Vickers submitted a formal proposal regarding the tank to the MOD following the issue of the staff requirement. In December 1988 it was announced that Vickers Defence Systems was to be awarded a £90 million contract to undertake a demonstration phase (also referred to as the proof of principle phase) which lasted until September 1990. Vickers Defence Systems acquisition was completed on 30 September 2002, by Alvis PLC. The operations of Vickers Defence Systems were merged with those of Alvis' existing UK armoured vehicle company,Alvis Vehicles Ltd, in a combined UK business. In order to benefit from the heritage and reputation of both Alvis and Vickers, it has been decided to call the combined UK company Alvis Vickers Limited (Telford, UK). This company was then acquired by BAE Systems, to form BAE Systems' new Land Systems business through the bringing together of Alvis and RO Defence. In June 1991 the British Government selected the Challenger 2 and placed an order worth £520 million for 127 Challenger 2 MBTs and 13 driver training tanks. Production began in 1993 and the first vehicles were delivered in July 1994. The Challenger 2 is produced at the Vickers Defence Systems plants in Leeds and Newcastle. There are over 250 subcontractors (both UK and Overseas) involved at some point in the manufacturing process. Among the most significant are: Royal Ordnance (Main and Secondary armaments); Blair Catton (Track); and GEC-Marconi (Gun Control). The requirement to replace Challenger 1 (CR1) MBT led to the placement of a follow-on order with Vickers Defence Systems. In July 1994, Vickers Defence Systems received a further order from the UK MOD for the supply of 259 Challenger 2 and nine driver training tanks plus training and logistic support. The total value of the contract was £800 million. The CR2 In-Service Reliability Demonstration (ISRD) milestone was successfully achieved in January 1999. The ISRD took place from September to December 1998 and tested 12 British Army crewed MBTs at the Bovington test tracks and Lulworth Bindon Ranges. The ISRD was a great success in that CR2 not only achieved the targets but exceeded them in all areas set by the Customer's Staff Requirement. The Royal Scots Dragoon Guards in Germany, the first of six post-SDR Armoured Regiments, started to take delivery of CR2 in January 1998 and received the 38th in time to meet the June 1998 in-service date. Deliveries of CR2 are continuing and it is planned that each of the six Armoured Regiments will be fully equipped with their tanks and associated logistic support package by end of 2000. The conversion from CR1 to CR2 Regiments is being assisted by a comprehensive suite of training aids, ranging from simple wall charts to highly sophisticated, computer-based gunnery simulators. A range of CR2 training aids and support equipment are also being provided for the Royal Electrical and Mechanical Engineers (REME) to assist the task of fault diagnosis, test, repair, calibration and system performance monitoring. The Challenger 2 (CR2) project includes the development and production of 386 CR2 Main Battle Tanks (MBTs), 22 Driver Training Tanks (DTTs), CHARM 3 ammunition and a full support package including training equipment and initial spares. Following international competition for a requirement to replace Chieftain MBT, a contract was placed with Vickers Defence Systems in June 1991 and included production of 127 CR2 MBTs and 13 CR2 DTTs. The requirement to replace Challenger 1 (CR1) MBT led to the placement of a follow-on order with Vickers Defence Systems during July 1994 for an additional 259 CR2 MBTs and nine CR2 DTTs. The CR2 In-Service Reliability Demonstration (ISRD) milestone was successfully achieved in January 1999. The ISRD took place from September to December 1998 and tested 12 British Army crewed MBTs at the Bovington test tracks and Lulworth Bindon Ranges. The ISRD was a great success in that CR2 not only achieved the targets but exceeded them in all areas set by the Customer's Staff Requirement. The Royal Scots Dragoon Guards in Germany, the first of six post-SDR Armoured Regiments, started to take delivery of CR2 in January 1998 and received the 38th in time to meet the June 1998 in-service date. Deliveries of CR2 are continuing and each of the six Armoured Regiments was fully equipped with their tanks and associated logistic support package by end of 2001. The last of the British Army’s 386 Challenger 2 Main Battle Tanks has been delivered by contractors at a ceremony on Salsibury Plain, by September 17, 2002. The conversion from CR1 to CR2 Regiments was assisted by a comprehensive suite of training aids, ranging from simple wall charts to highly sophisticated, computer-based gunnery simulators. A range of CR2 training aids and support equipment was also provided for the Royal Electrical and Mechanical Engineers (REME) to assist the task of fault diagnosis, test, repair, calibration and system performance monitoring. Deployed with six Regiments of the Royal Armoured Corps in the UK and Germany, the Challenger 2 Main Battle Tank has seen service in Bosnia and Kosovo and exercised in Canada, Oman and Poland. It has surpassed reliability targets on both trials and on exercises. British Army Challenger 2 tanks were deployed on active service in Operation Iraqi Freedom. In July 2004, the UK Ministry of Defence announced plans for a reduction of seven Challenger 2 armoured squadrons (about 100 tanks) by March 2007 and the change of role of one Challenger 2 regiment to an armoured reconnaissance regiment. Challenger 2E, the latest development model, has been designed for the export market and is suitable for harsh environmental and climactic conditions. The 2E has been extensively trialled in Greece, Qatar and Saudi Arabia. New Main Gun for the Challenger 2: The Rheinmetall 120mm

L55.

In January 2004, BAE Systems Land Systems (formerly RO Defence) was awarded a contract to develop a new smoothbore 120 mm gun for the British Army Challenger tanks. Under the contract, a Challenger 2 has been armed with the new Rheinmetall L55 smoothbore gun, as fitted on the Leopard 2A6 main battle tank, and began firing trials in January 2006.

Ballistically the new weapon is the same as the German 120 mm L/55 but externally can fit into the space previously occupied by the L30. The current Challenger 2 installation retains the L30 rifled gun's cradle, gun clamp, thermal sleeve, fume extractor and muzzle reference system. Following trials in Germany the weapon was also tested in a static mount installed on a Centurion MBT chassis in mid-2005 and later in the same year, was finally integrated into a Challenger 2 MBT. This upgrade will enable the British main battle tank to use NATO-compliant 120mm ammunition. Static firing trials have already been conducted against a wide range of targets firing the Rheinmetall 120 mm DM53 APFSDS projectile with a conventional penetrator. These trials, although classified information, seem to have shown that the DM53 round gives enhanced performance over the previous 120 mm Challenger Armament - CHARM 3 - firing a depleted uranium round. Challenger 2E

Challenger 2E has been specifically designed for demanding environmental and climatic conditions and represents the latest evolution of the highly effective family of Challenger vehicles.

The Challenger at the Gulf War.

An up-armored Challenger 1 of the Royal Hussars, during the Gulf War. The Vickers Challenger was bought for the British Army after the Shah of Iran was deposed and the order blocked. It was developed from the Chieftain but was much faster, better armed and armoured but suffered from a weak fire control system. The Challenger gave the British Army a state-of-the-art tank ten years before any replacement for the Chieftain was scheduled. The Challenger was made for the desert, but did not have the chance to win its spurs until the Gulf War. Actually, Vickers did not manufacture all the Challenger 1 MBTs, only the last regiment. Challenger 1 was built at the Royal Ordnance Factory (ROF) Leeds (it became Royal Ordnance in preparation for privatization), which Vickers bought just before the order for the 7th regiment was placed. Fitted with a 120mm L11 A5 gun, the Challenger's only weakness was its fire-control system, which had been upgraded by the Gulf War. The gun could penetrate 400mm of armour and destroy any Russian-built tank with a single hit. With nearly all of Iraq's' tanks being Russian built, the Challenger was able to deal with them easily. Backed up by the massive air support and alongside the Arab, French and American tanks the Allied armour ripped through the Republican Guard without much trouble. The Challengers in Desert Storm mainly employed HESH (High Explosive Squash Head) shells with their longer range as the Iraqi tanks armour wasn't up to Russian standards and would have been a waste of the shorter-ranged high-density armour-piercing rounds. TURRET AND HULL The tank accommodates four members of crew, the commander, gunner, driver and the loader, for increased fightability and effective round-the-clock operation, which is strongly influenced by the number of crew which can be carried. The commander's station is on the right and is equipped with eight periscopes, magnification x 1, which provide 360 degree vision. Pushing a red command button under each periscope causes the turret to slew round to align with the periscope. The gunner is seated in front of and below the commander, and the loader is seated on the left. The loader's station is equipped with a periscope. The driver's compartment is at the front of the tank. WEAPONS

Challenger 2 is equipped with an L30, 120 mm rifled tank gun from the Royal Ordnance division of British Aerospace Defence Ltd at Nottingham, UK. The L30 construction incorporates a chromium lining which provides a harder and smoother internal surface. The chromium lining gives increased velocity and therefore penetration power to the round, greater precision and reduced wear on the barrel. The gun is made from electro-slag refined steel (ESR) and is insulated with a thermal sleeve. The gun is fitted with a muzzle reference system and fume extraction to remove the gasses from the barrel. The turret is capable of 360 degree rotation and the weapon elevation range is from -10 to +20 degrees. The target engagement sequence has been designed for simplicity of operation in battlefield conditions. The same engagement sequence is followed for static and moving targets in daylight or by night. The gunner or the commander aligns an aiming mark on the target, presses the laser rangefinder button and then presses the fire button. The 120 mm L30 gun fires all current 120 mm ammunition. There is capacity for 50 projectiles, which can be a mix of armour piercing fin stabilized discarding sabot (APFSDS), high explosive squash head (HESH) or smoke rounds. The L30 gun can also fire the Depleted Uranium (DU) round with a stick charge propellant. Depleted Uranium has a density approximately two and a half times higher than that of steel and the mass of the DU projectile provides high penetration characteristics. The first depleted uranium round, the L30, is part of the Charm 1 gun, charge and projectile system. A Charm 3 system is under development in which the depleted uranium projectile has a higher length to diameter aspect ratio for increased penetration performance. The ammunition, being of the separate projectile and charge loading type, allows the explosive ammunition to be stowed below the turret ring. Armoured bins provide the stowage for the charges. The gun control is provided by an all-electric gun control and stabilization system from GEC Marconi Radar and Defence Systems of Leicester, UK. The Challenger 2 is also equipped with a McDonnell Douglas 7.62 mm chain gun, which is located to the left of the main tank gun. The loader seated on the left hand side has a 7.62 mm GPMG anti-air machine gun, type L37A2, mounted on the cupola. On each side of the front of the turret are five L8 smoke grenade dischargers, from the Helio Mirror Company of Kent, UK. The Challenger 2 can also set a smoke screen by the injection of diesel fuel into the engine exhausts. The Challenger 2 is equipped with a Military Standard 1553 data bus. The fire control computer is a digital computer from Computing Devices Company of Ontario, Canada. The digital CDC computer has capacity for additional systems, for example a Battlefield Information Control System, and navigation and training systems. In January 2004, BAE Systems' Land Systems was awarded a contract to develop a new smoothbore 120mm gun for the British Army Challenger tanks. Rheinmetall of Germany will provide examples of the L55 smoothbore gun fitted on the Leopard 2A6 for the program. A technical demonstrator will be produced by 2006. SENSORS The commander has a Gyrostabilized site, model VS 580-10, from SFIM Industries of France. The upper unit of the VS 580, containing the Gyrostabilized panoramic sight and electronics, is mounted on the turret roof. A neodinium yttrium aluminium garnet, Nd:YAG, laser rangefinder is incorporated into an intermediate assembly which joins the upper unit to a lower telescope assembly inside the turret. The telescope assembly houses the optical viewing system, hand controls, electronics and the sight stabilization system. The sight provides all round vision without the commander having to move his head. The elevation range is plus or minus 35 degrees. The field of view with x 3.2 magnification optics is 16.5 degrees, and with x 10.5 magnification optics, the field of view is 5 degrees. A thermal imager, the Thermal Observation and Gunnery Sight II, TOGS II, from Pilkington Optronics of Glasgow, UK, provides night vision. The sensor is the UK TICM 2 thermal imager. The imager is mounted inside an armoured barbette above the gun. An on-board compressor and gas bottle pack provide cooling for the imager. Symbols are overlaid on the thermal image to show the aiming marks and system status data. The thermal image, with magnification x 4 and x 11.5 is displayed in the gunner's and commander's sights. The thermal image is also displayed on relaxed-viewing monitors in the commander's and gunner's stations. The gunner has a stabilized Gunner's Primary Sight, GPS, from Pilkington Optronics of Glasgow, UK. The sight consists of a sight body with a visual sighting channel, a head unit with a stabilized aiming mirror, a 4 Hz neodinium yttrium aluminium garnet Nd:YAG laser rangefinder and a display monitor with a monocular eyepiece. The laser rangefinder with wavelength 1.064 microns, operates over the range 200 meters to 10 kilometers. The range accuracy is plus or minus 5 meters and the discrimination is 30 meters The gunner is also equipped with a reversionary mode telescope, model L30, from Nanoquest, mounted coaxially with the main gun. The driver is equipped with a Passive Driving Periscope, PDP, from Pilkington Optronics. The periscope uses a night vision image intensifier device. At night the tank is able to achieve speeds comparable to day-time speeds using the passive driving periscope and without the use of artificial light. The Military Standard 1553 data bus interfaces the Gunner's Primary Sight and the thermal imaging system to the fire control computer. ENGAGEMENT PROCEDURE  Challenger 2, negotiating rough ground. The commander aligns the roof mounted panoramic sight on a target and presses the align switch to slew the turret round until the gun is automatically positioned on the target. The gunner then takes over the engagement of the target, and presses the laser rangefinder and the fire buttons to fire the gun. As soon as the gunner has taken over the engagement of the target, the tank commander is able to locate and take range measurement of a second target using the commander's sight. The data for both targets, the first target being engaged by the gunner and the second target, are stored in the digital fire control computer. When the gun has been fired and the kill assessment on the first target completed, the commander presses the align switch which results in the turret slewing round to align the gun on the second target and automatically firing the gun. The operational procedure greatly enhances the firepower of the tank, in that the Challenger can effectively engage targets in rapid succession. SAFETY  The Challenger 2 MBT is one of the heaviest and best protected tanks in the world. The design of Challenger 2 has given emphasis to crew safety and tank survivability. The turret is protected with second generation Chobham armour which provides increased resistance to penetration by anti-tank weapons. The tank is protected against nuclear, biological and chemical (NBC) warfare by an NBC protection system (with full overpressure filtered air) located in the turret bustle. The electronics systems are protected against nuclear electromagnetic pulse (EMP). The movement of the turret and gun is by a solid state electric drive rather than by high pressure hydraulic drive. The electric drive removes the risk associated with rupturing of high pressure hydraulic hoses in the crew compartment. The stowage for explosives is below the turret ring which provides a less vulnerable position than in the turret bustle. The turret and the hull designs incorporate stealth technology to minimize the radar signature. TRIALS Challenger 2 has successfully completed trials with the British Army and the Royal Army of Oman. All the performance parameters were demonstrated, including the weapon systems, reliability and survivability. The performance of the Chobham armour was demonstrated in repeated firings trials on the Challenger 2 turret with modern anti-tank weapons. The result of the trial was that the complete turret survived without penetration and the sighting system allowed the gun to be laid and fired. PROPULSION  The Challenger 2 making its 1,200 HP engine do "some excercise"... The Challenger 2 has a 12 cylinder 1200 horsepower diesel engine, from Perkins Engines (Shewsbury) Ltd of Shropshire, UK., and a David Brown gearbox, model TN54, with 6 forward and 2 reverse gears. The maximum speed by road is 59 kilometer/hour and mean speed 40 kilometers./hour cross country. The range is given as 450 kilometers. by road and typically 250 kilometers. cross country. Challenger 2 characteristics, technical performance, and specifications:

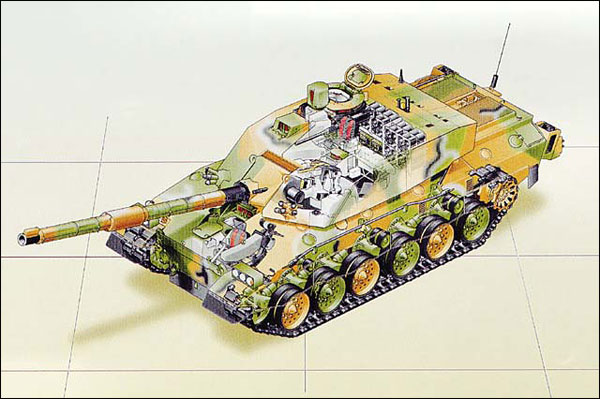

Challeger 2 cutout drawing. General characteristics / technical performance Engine: Perkins Condor CV12 1200bhp SPECIFICATIONS

RESOURCES Army Technology - Current Projects Website FAS - Military Analisys Network The Gulf War - 1991 - Operation Granby The ARMOR Site! is © Copyright 1997-2006 Fabio Prado . All Rights Reserved. |