EE-T1 Osório Main Battle Tank Introduction Engesa was formed as a private firm

in 1963. Initially, it was involved in renovating World War II-vintage

tanks. Engesa built wheeled APC's, such as the EE-11 Urutu amphibious

APC, the EE-9 Cascavel armored reconnaissance vehicle, the EE-17

Sucuri tank destroyer, and the EE-3 Jararaca scout car, in addition

to a wide range of other products. The EE-11 Urutu armored troop

carrier is an amphibian that can also be used by naval forces. It

is still used by the Brazilian Army. It made a success in the international

sales market, and is in service ia at least six Armies worldwide,

in addition to the Brazilian Army. In terms of product development,

all of Engesa’s armored fighting vehicles and armored personnel

carriers shared the same characteristics: simple and flexible design

concepts, low cost, good performance and reliability, ease of use,

and simple maintenance. These characteristics were the major selling

points of Engesa’s products to its customers in the developing

countries. Engesa's APC's were all based on a new proprietary suspension system, called "Engesa Boomerang". This ingenious suspension system, along with many other modifications, expanded the life span of many otherwise obsolescent World War II-vintage vehicles. Engesa's weapons were exported almost exclusively to the developing world, especially to countries in the Middle East, Latin America, and Africa. By the mid-1980s, Engesa had expanded to a group of twelve subsidiaries and employed more than 5,000 people.

Chronology of Main Battle Tank development in Brazil:

Brazil emerged in the mid-1980s as the leading arms producer and exporter among the defense industrializing countries, and the sixth largest arms exporter in the world. Although there were over 500 manufacturers of defense-related equipment in Brazil, three firms have been largely responsible for Brazilian defense exports: in aircraft, Embraer; in armored fighting vehicles, Engesa; and in missiles, Avibras. Engesa was well positioned to take advantage of Brazil’s nonaligned position in the international system and its affinity with other developing nations. The company has exported its armored and reconnaissance vehicles to over 20 countries in the Middle East and Africa. Annual export earnings amounted to over US$53 millon for the 1977-82 period and US$122 million for the 1983-88 period. The largest regional market was the Middle East, to which Brazil sold roughly half of its arms from 1977 through 1988, with nearly half of all Brazilian arms transfers from 1985 to 1989 going to Iraq. A related factor was Engesa's well-known after-sales support in terms of guaranteed access to spare parts, training for system operators, and maintenance (including front-line repair during the Iran-Iraq war). However, with the end of the Iran-Iraq war and the decline in state support, the Brazilian arms industry collapsed in the late 1980s, and by the mid-1990s had virtually disappeared. In early 1990, Brazil's two major manufacturers, Engesa and Avibras, filed for bankruptcy. Engesa has been dismembered, with some of its companies sold to private interests, and ordnance-related firms taken over by the state and integrated with the Indústria de Material Bélico do Brasil (IMBEL - Brazil's Industry of War Weapons and Equipments).

Development and Production History.

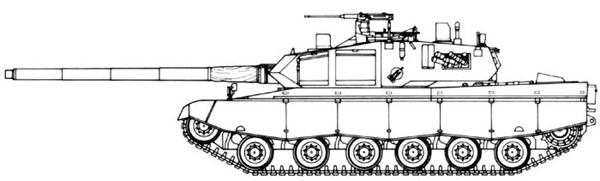

In the early 80's, Saudi Arabia began searching for a new main battle tank (MBT), with the objective of replacement for their AMX-30 MBT's. At first, they wanted the Leopard 2, which had just began to be received by the Bundeswehr, as the Saudis were impressed with the success of the Leopard 1 both in Germany and in other European countries as well. However, the German government refused to sell weapons to countries that were not NATO's members. This way, a new market was opened, and Engesa decided to go for it. At first, Engesa searched for a partner for the project's development, and contacted Tyssen-Henschel in Germany, but the conversations came to nothing. Then, Porsche showed interest in participating in the Brazilian MBT project. However, the German government once again intervened and the German-Brazilian cooperation project was cancelled. That being the situation, Engesa decided to go on with the project by itself, a decision that would prove later to be too risky. In face of the way the Brazilian state participated in the Brazilian armament industry at that time, some restrictions imposed by the Brazilian Army had to be considered. The first one stated that the new MBT should weigh no more than 36 tons, which was a technical impossibility, as it would set the Brazilian MBT outside of the first class MBT's weight, which was between 44.5 tons (T-72) and 62 tons (Challenger), at that time. The second Brazilian Army's restriction was that the maximum width of the new MBT could not be larger that 3.20 meters, a limit imposed by the Brazilian railway structure. Engesa's engineers accepted the second restriction, but rejected the first, and the target weight was stipulated as 42 tons, on grounds that most of the transportation would be realized by roads, anyway. Another important decision was that the development would consist of a basic chassis and two different types of turret, allowing the possibility of two different main gun possibilities: the 105 mm and the 120 mm. Engesa was determined that the first prototype had to be ready in one year, so the company decided that it would develop the project of the chassis, and the projects of the two turrets were to be realized by Vickers Defence Systems, Great Britain.  The first turret, the "default", was designed to accommodate the British 105mm L7 series gun, which was NATO's main battle tank gun specification, until the 120 mm L/44 Rheinmetall gun was adopted, but that was still to happen in the future. The British 105 mm L7 series gun was an excellent option, because it was used by many countries, was a tried and proven weapon, its cost was reasonable, and there were many types of ammunition available for its use. The fire control system for this turret, fully computerized, consisted of a laser range finder and a LRS-5DNLC Olp Belgian periscope, and the commander had an LRS-5DN periscope. This fire control system and the main gun were fully stabilized.

The second turret was developed for being used by the Saudi Arabia's Army. This turret would receive the French smooth-bore 120mm GIAT G1 gun, because tests proved that the British rifled 120mm L11 gun had stronger recoil forces, that a 42 ton MBT would not support. The German Rheinmetall 120 mm L/44 smooth-bore gun was not tested because of the weapons selling politics of the German government at that time. As a result of all that, the tank was either armed with an L7 105mm gun with 45 rounds stowage or a GIAT 120mm gun with 40 rounds. One 7.62 mm MG was mounted coaxial, another one (or 12,7mm) was used as ADMG (5000 rounds / 3000 7.62mm 900 12,7mm). The 105 mm rifled gun was the well proven British L 7 series, with a fume extractor, and a thermal sleeve. Various kinds of ammunition were used with this gun including: APDS, APDSFS, HEAT, HESH, and Smoke. The 120 mm was a French GIAT smooth bore gun, firing APDSFS-T and HEAT-MP ammunition. Both the guns with their respective ammunition were to be produced under license in Brazil, by Engesa.

The computerized fire control system, by Marconi Command and Control Systems, used a SFIM stabilized periscope with laser range finder for the gunner and another one for the commander. A Philips/TRT stabilized thermal periscope was linked to both sights. This fire control system was state-of-the-art and assured a very high first round hit probability. Initially, Engesa wanted to use an MTU engine, since they were used with great success with the Leopard 1 and 2, and also because MTU already was operating in Brazil. But its price was way too high, and the MWM 1,000 hp diesel TBD 234 turbo charged diesel engine was selected, coupled to a ZF LSG 3000 transmission. Both companies, MWM and ZF, were already operating in Brazil. This engine was tested for over 3,000 km in Saudi Arabia, and proved to be most efficient and easy to maintain. The suspension was of hydro pneumatic type (like the one used by the British Challenger) and designed by Dunlop. The Osório MBT was provided by an auxiliary power unit in the left hull rear. Fuel capacity was of 1354 liters. The EE-T1 Osório armor was entirely developed by Engesa and was a combination of aluminum/steel and carbon fibers and ceramics (bimetal+composite/laminate armor). This armor was said to provide complete protection against all HEAT threats existent at that time. The Twilight of the EE-T1 Osório Main Battle Tank Project.

The Osorio MBT exemplifies the way Engesa approached development of new weapon systems. First, following the Saudi Arabian requirements for a light main battle tank, the company conducted a market feasibility study of other developing countries, where bridges and roads could not support MBTs within the 60 ton class such as the U.S. M1A1 Abrams, the German Leopard 2, or the British Challenger. Second, Engesa searched for the best available armor, engines, suspension system, electronics, and gears. In keeping with its strategy of finding suppliers who would share the development costs, Engesa succeeded in attracting many international defense equipment suppliers because the Osorio MBT program represented the only new tank development project in the 1980s and 1990s. For example, Dunlop, supplier to the British Challenger MBT, was willing to provide the Osorio’s hydropneumatic suspension system (which keeps the tank lower on the ground than the more conventional torsion bar suspension). Within Brazil, Engesa could rely once more on the transnational automotive industry, particularly West German companies, to supply the diesel engine and the gear box. The development of this MBT also reflects the inherent difficulties facing a company based in the developing world in moving up the high-technology ladder to the production of more advanced weapon systems. First, the financial resources required are enormous. Since Saudi Arabia gave the go-ahead for prototype production of the Osorio in 1985, Engesa proceeded to spend US$100 million in R&D and prototype development. This design of the Brazilian armaments industry was sophisticated, and demanded a high investment in technology. It was equipped with computers and endowed with a modern weapons system. The EE-T1 Osório Main Battle Tank was an advanced design in all aspects of tank development (Firepower, Protection and Mobility), which resulted in high standards within its weight category. However, by the mid-1980s, Engesa was unable to find a buyer for it. Despite an announcement in August 1989 by the Saudi Government that they were going to buy 318 Osorios (renamed Al Fahd, the Lion Of The Desert), the contract (worth US$7.2 billion) was never signed. In April 1990, after laying off 3,000 workers, Engesa filed for bankruptcy protection. Even though in 1990 Engesa had won the evaluation process by the Saudis, the Osório project came to an abrupt end with Operation Desert Storm against Iraq in 1991. After Desert Storm, Brazil was no match for United States competition, given the close ties that developed between Saudi Arabia and the United States and, last but not least, the outstanding performance of the M1A1 Abrams during the war with Iraq.

RESOURCES FAS - Military Analisys Network Armas de Guerra do Brasil (Brazil's Weapons of War): Editora Nova Cultural Ltda., São Paulo, Brasil, 1989 (in Portuguese). MBT Osório, by Reginaldo da Silva Bacchi (in Portuguese). The ARMOR Site! is © Copyright 1997-2006 Fabio Prado . All Rights Reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||