In early 1970, the German Ministry of Defense recommended the development of the 'Vergoldeter Leopard' to be continued with the adoption of the MTU engine developed for the MBT/Kpz-70 in order to take advantage of the further experience that had already been acquired with it. Another seven vehicles were ordered, with Krauss-Maffei again chosen as the main contractor. The prototypes looked at

first glance very much like the Leopard 1 A4, but with a

wedge-shaped bow and an exhaust grille moved to the rear

plate. The roadwheels came from the MBT/KPz-70, and the return

rollers from the Leopard 1. The engine also came from the

MBT/KPz-70, a 12 cylinder MTU MB-873 Ka-500 water-cooled

multi-fuel four-stroke engine, together with its 20 kW generator,

gearbox, air filters, and the cooling and braking systems,

forming a compact group that could be easily replaced in

15 minutes. Ten of the seventeen turrets built were fitted

with a 105 mm smooth bore gun while the remaining seven had

a 120 mm smooth bore gun, both designed and produced by Rheinmetall. During 1973, negotiations began between the United States and Germany to standardize certain components of both nations main battle tanks of the eighties. As a result of this, by 1976 it was agreed to study how Leopard 2 could be modified to meet US performance and constraints. Based on the altered German and US military demands, Porsche, Krauss-Maffei, and Wegmann designed and built the Leopard 2 AV (Austere Version).

Modifications included the new multi-layered (much like the British developed "Chobham" armor, which consisted of layers of steel and ceramics) armor on the hull and a new turret with a less sophisticated fire control system. Two chassis and three turrets were built, and were ready in 1976. The first prototype had a turret with a Hughes fire control system and a L7A3 105 mm main gun. The second one was equipped with the same gun, but provisions were made to allow a quick adoption of the Rheinmetall 120 mm smooth bore main gun. The third turret had a German fire control system, including the EMES 13, and was to be used in the German test program. An additional turret was built and was identical as the third, but had the Rheinmetall 120 mm smooth bore main gun installed from the beginning. The Leopard 2 AV was originally intended to be tested as the same time with the XM1, but the German modification program took longer than expected. The US Army therefore proceeded with the evaluation of the XM1 prototypes built by Chrysler and General Motors, and ultimately decided to launch full-scale development of the Chrysler design. However, the German prototypes arrived in the US by the end of August 1976 and comparative tests between the Leopard 2 AV and the XM1 prototypes were done at Aberdeen Proving Grounds, lasting until December 1976. The US Army reported that the Leopard 2 AV and the XM1 were comparable in firepower and field mobility but the XM1 was superior in armor protection, and so the XM1 was selected. After the comparative test the Leopard 2 AV prototypes were returned to Germany for further evaluation tests. In September 1977 the German MoD formally decided to go ahead with plans for production of 1,800 Leopard 2, which were to be delivered in five batches. From the original group of companies bidding for the contract, Krauss-Maffei was chosen as the main contractor and systems manager. MaK became sub contractor and production was to be shared between the two companies on the basis of 55% for Krauss-Maffei and 45% for MaK. Wegmann, as turret integrator, received full responsibility for coordination the integration of the EMES 15 fire control. The EMES 15 fire control was developed by Hughes in cooperation between Krupp Atlas Elektronik, with the 120 mm smooth bore high-performance main gun supplied by Rheinmetall with the turret. Without doubt, at the time of its introduction (1979), the Leopard 2 was the most advanced tank in the world. The Germans succeeded in designing a tank with high success in all three areas of tank design: mobility, firepower, and armor protection. Until then, tank designers had only been able to achieve two of these objectives at once. The British Chieftain, for instance, had a pretty good gun and good armor, but very poor mobility. At the other end of the scale was the French AMX-30, which had good mobility, an adequate gun, but weak armor. SERIES PRODUCTION

A total of 380 Leopard 2 were built in the first batch, 209 by Krauss-Maffei (chassis nbr. 10001 to 10210) and 171 by Mak (chassis nbr. 20001 to 20172), with the first six delivered in 1979 to Kampftruppenschule 2 in Münster. Another 100 were delivered in 1980 and 229 in 1981, replacing the M48A2G in units among I (GE) Corps. The first Leopard 2 went to Panzerbattalions 31, 33 and 34 of 1 Panzerdivision, with partially parallel delivery to Panzerbattalions 81, 85 and 84 of 5 Panzerdivision. The Leopard 1s then in service were passed to the Panzerbattalions of the Panzergrenadier Divisions, were they replaced the M48A2G. By 1982 production was running at 300 a year, with the last first batch Leopard 2 delivered in March of that year. The combat weight of the Leopard

2 is 55,000 kg, empty weight being 52,000 kg, and its hull

has spaced multi-layer armor. The running gear consists of

seven dual rubber-tyred road wheels and four return rollers

per side, with the idler wheel at the front and drive sprocket

at the rear. The driver's station is located at the front, offset to the right of the vehicle's center line. A large, pintle-mounted lift-and-swing type hatch is provided for the driver and opens to the right. There are two observation periscopes in the driver's hatch, plus one to the left of his section, for use when driving closed down. The central periscope (in the hatch) can be exchanged for a passive IR-sight for night operations. An escape hatch is provided under the driver's seat. The turret, incorporating multi layer armor, is mounted in the center of the hull and is manned by the commander and gunner in the right half, with the loader in the left half. The commander and the loader each have a circular hatch, opening to the rear, and six periscopes provide all-round vision for the commander. Both hatches have ring mounts for the 7.62 mm MG-3 air defense machine gun, though it is normally installed on the loader's hatch.

The 120 mm Rheinmetall main gun is fully stabilized in both azimuth and elevation, and the WNA-H22 electro-hidraulic gun control system is fitted. The gun fires two types of ammunition, both developed by Rheinmetall APFSDS-T, known as DM-33 KE (Kinetische Energy), and HEAT-MP-T, known as DM-12 MZ (Mehrzweck = multipurpose), both types having combustible cases. 27 rounds of 120 mm ammunition are stored in a special magazine in the forward section of the hull, to the left of the driver's station - additional 15 (making a total of 42) are stored in the left side of the turret bustle, and separated from the fighting compartment by an electrically operated door. Should the ammunition in the bustle be hit, blow-off panels in the turret roof would direct any explosion upwards. A co-axial 7.620mm MG 3is mounted to the left of the main gun and 4,750 rounds of machine gun ammunition are carried.

The thermal sight for the gunner's EMES 15 primary sight was not ready during production of the first batch, though all vehicles were prepared to be so equipped at a later stage. To provide an improvised night fighting capability for first batch vehicles, the Panzer-Ziel-und-Beobachtungsgerät (PZB) 200ow light TV system (LLLTV) was temporarily fitted to 200 Leopard 2 The EMES 15/FLT-2 fire control system consists of:

The gunner also has an auxiliary

telescope FERO-Z18 with a magnification of x8, mounted co-axially

to the right of the main gun. An independent and fully stabilized

PERI R-17 primary panoramic sight, made by Carl Zeiss and

with magnifications of x2 and x8, is installed at the front

of the commander's station. This sight can be traversed through

360 degrees and allows the commander to override the gunner's

control if necessary. An ammunition supply hatch opening

outward, is provided in the left side of the turret side.

Two groups of four 76 mm Wegmann smoke mortars are mounted

on either side of the turret and can be electrically fired

either as single rounds or in salvos of four. The engine compartment is

at the rear, separated from the fighting compartment by a

fireproof bulkhead. The MTU MB 873 Ka-501 liquid-cooled 47.6

litre V-12 cylinder 4-stroke exhaust turbo-charged diesel

engine develops 1,104 kW (1,500 PS) at 2,600 rpm. It is started

by eight 12-volt/125 Ab batteries and has a 24-volt electrical

system. The Leopard 2 maximum road speed is 68 km/h, though

it is limited to 50km/h during peacetime, and top reverse

is 31 km/h. Four 9 kg Halon fire extinguisher bottles are installed on the right behind the driver's station. The bottles are connected to pipes and hoses and are activated automatically by the fire detection system, when temperatures rise above 180° F inside the fighting compartment, or manually via a control panel in the driver's compartment. An extra 2.5 kg Halon fire extinguisher (HAL 2.5) is stored on the floor beneath the main gun. The Leopard 2 has a self-contained NBC protection system, which produces up to 4 mbar (0.004 kp/cm²) over pressure inside the vehicle. The Leopard 2 is able to ford water obstacles 1.20 m deep (wading) without any preparation, and to ford at a depth of 2.25 m (deep wading) with special preparation. About 15 minutes preparation is required to get the tank ready for crossing water obstacles at a depth of 4 ma (underwater driving), including the fitting of a special three-piece snorkel to the commander's cupola. Production of the second batch began in March 1982 and ended in November 1983. Of the 450 vehicles built, 248 were built by Krauss-Maffei (chassis nbr. 10211 to 10458) and 202 by MaK (chassis nbr. 20173 to 20347). The most significant changes were the deletion of the cross wind velocity sensor, and that the protection over the optical blocks at the commander's station was now faceted shape. The tank thermal sight, based on the common modules provided by Texas Instruments and built by Carl Zeiss, was now fitted to the gunner's EMES 15 primary sight and the gun control system was included in the fault detection system. The fuel filters were repositioned, considerably reducing the time required for refuelling. An external head-set connection was added to the left rear of the turret side. The racks of ammunition stowage were identical to those that were to be fitted to the M1A1 Abrams. Two foot boards were attached to the power pack, thus avoiding damage to the steering system and the electrical wiring and plugs during maintenance with the deck removed. The tow cable clamps on the rear deck were repositioned and the cables, now 5 m long, were crossed on the rear plate. Due to these numerous changes, this version was designated the Leopard 2 A1 . The 300 Leopard 2 of the third batch were built between November 1983 and November 1984, 165 by Krauss-Maffei (chassis nbr. 10459 to 10623) and 135 by MaK (chassis nbr. 20375 to 20509). The most notable changes were the addition of a deflector, which raised the position of the commander's PERI R-17 primary panoramic sight by 50 mm, and a larger cover plate fitted on top of the NBC protection system. These modifications were subsequently also carried out to the second batch vehicles. The third batch vehicles were also designated Leopard 2 A1 . The fourth batch was built between December 1984 and December 1985. Of the 300 vehicles delivered, 165 were built by Krauss-Maffei (chassis nbr. 10624 to 10788), and 135 by MaK (chassis nbr. 20510 to 20644). The most significant changes were the installation of new digital SEM 80/90 VHF radios and revised exhaust grilles with circular bars. The ammunition supply hatches were welded shut (risk of leaking if turret was hit). The vehicles of this batch were designated the Leopard 2 A3 .  Leopard 2A3, Panzerbattalion 123, Panzerbrigade 12, October 1990. Between December 1985 and March 1987, 370 vehicles were delivered, with 190 being built by Krauss-Maffei (chassis nbr. 10789 to 10979), and the remaining 180 by MaK (chassis nbr. 20645 to 20825). In this batch, the fire control was fitted with a digital core to facilitate the use of new ammunition, and to improve the crew's survivability a fire and explosion suppression system developed by Deugra was installed. The return rollers were repositioned. The turret protection level was increased to more than 700mm for KE and 1000mm for HEAT. The vehicles of this batch were designated Leopard 2 A4 . Although only five batches were originally intended to be built, an order for a sixth batch of 150 vehicles was placed in june 1987, and 83 were built by Krauss-Maffei (chassis nbr. 10980 to 11062) and 67 by MaK (chassis nbr. 20826 to 20892), between January 1988 and May 1989. New features in this batch were the installation of maintenance-free batteries, the introduction of Diehl 570FT tracks, and the use of zinc cromate free paint. The central warning light was now installed in a small housing on the hull, in front of the driver's station, for better observation by the driver when driving head-out.The ammunition supply hatch in the left side of the turret was deleted. The vehicles of this batch were also designated Leopard 2 A4 . |

|||||||||||||

Production of 100 seventh batch vehicles began in May 1989 and ended in April 1990, with 55 built by Krauss-Maffei (chassis nbr. 11063 to 11117) and 45 by MaK (chassis nbr. 20893 to 20937) . The vehicles of this batch were identical to the late sixth batch vehicles and also called Leopard 2 A4 .

Leopard 2A4 (seventh batch), Panzerbattalion 214, 7.Panzerdivision, CMTC Hohenfels, December 1995.

Between January 1991 and March 1992 75 vehicles were delivered, with 41 built by Krauss-Maffei (chassis nbr. 11118 to 11158) and 34 by MaK (chassis nbr. 20938 to 20971). Changes included slight modifications of the base mounts for the smoke mortars, and later on a collimator for the muzzle reference system was fitted to the right side of the 120 mm main gun, near the barrel's end, and was subsequently retrofitted to the vehicles of previous batches. The muzzle reference system allows a quick check for the gunner of the distortion of the gun barrel in relation to the sight optics. The vehicles of this batch were also designated Leopard 2 A4 .

The final Leopard 2 A4 of the eight batch was delivered to the Gebirgs-Panzerbattalion 8 (Mountain Tank Battalion) on 19 March 1992, in a official ceremony in Munich.

Leopard 2A4 of Panzerbattalion 393, December 1995. CMTC Hohenfels. |

After delivery of the last eight batch vehicle, there were 2.125 Leopard 2 A4 in service with the Bundeswehr. The Leopard 2 was designed to meet the requirements of modern mobile combat to counter the Soviet threat to Central Europe. It used the most advanced technologies available at the time, to achieve enhanced performance, with optimal results in the combination of armor protection, firepower, and mobility; which placed it among the leaders in modern tank design.

THE IMPROVED LEOPARD 2 - LEOPARD 2 A5 KWS II

|

| Leopard 2A5 KWS II: new turret and third generation composite armor. (Photo: Krauss-Maffei Wegmann GmbH & Co. KG.) |

In a modern world the pressure for modernization is a matter of course, but in the field of military technology it is a bitter reality. With the appearence of modern and capable Soviet tanks such as the T-64 B and T-80 B, equipped with a high-performance 125 mm smoothbore gun capable of firing guided missiles, the development of an even better Leopard 2 was demanded. However, cooperation between nations over their tank industries can be difficult. After the cancellation of a joint French-German tank development project in November 1982, Germany extended the concept phase for a Leopard 3 in March 1983 to last until 1996. Several alternatives had to be examined, including production of additional Leopard 2, improvement of the Leopard 2, development of a new turret for the Leopard 2 with a crew of four or with a crew of three with an automatic loader, or still the development of an entirely new hull and turret.

The development of improved components for the Leopard 2 was finally favoured, and in 1989 the Leopard 2 KVT (Komponentenversuchsträger - component trial vehicle) was built and tested. This vehicle was fitted with additional armor, spall liners in the fighting compartment, a new electrically-driven sliding hatch for the driver, new hatches for the commander and loader, and increased reactive and passive armor on the turret roof. The EMES-15 was raised and received an armored housing, and the PERI-17, now including an independent thermal sight channel, was relocated to the left rear of the commander's section. This prototype had a total weight of 60,500 kg. After the trials, this vehicle was converted into the IVT (Instrumentenversuchsträger - experimental vehicle for instruments) and joined the IFIS (integrated command and information system) development program carried out between 1988 and 1992, which researched in cooperation with the US the more efficient way to the management and use of gathered information. After evaluation of the development tests with with the KVT, two prototypes were built in 1991 by Krauss-Maffei for the improvement program, known as KWS.

The overwhelming political changes within the Eastern Block, and the resulting decreasing defense budgets definitely modified the improvement program. An alternative improvement program was initiated, divided into three stages, and known as KWS I, KWS II, and KWS III (the Roman numerals do not denote chronological order).

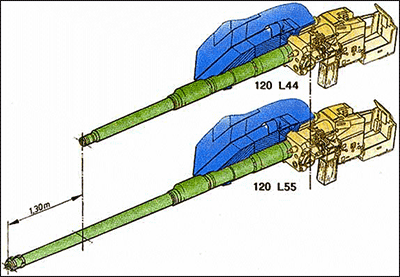

KWS I consisted of the adoption of a longer L/55 120 mm main gun and the use of improved ammunition, having an increased muzzle velocity of 1,800 m/s (OBS: This program resulted in the Leopard 2 A6).

KWS II was the development of increased armor protection for the crew and improved command and control system capabilities (OBS: This program resulted in the Leopard 2 A5).

KWS III consisted of the adoption of a 140mm main gun.

|

|

| Prototypes of the Leopard 2 with the 140 mm gun. | |

On October 1991, Switzerland, the Netherlands, and Germany decided for cooperation in a development program for KWS II. The first Leopard 2 A5 were officially delivered to the German Army School on 30 November 1995. Chassis of the sixth, seventh, and eight batches were to be used for the conversion program and to receive reworked and modified turrets taken from tanks of the first four batches. Modernization of the chassis were to be carried out by Krauss-Maffei and MaK while Wegmann and Rheinmetall became responsible for the turrets.

The most significant change to the hull of the Leopard 2 A5 is the new driver's hatch, which is now electronically operated and slides to the right to open. A deflector is mounted to the left of the driver's station, with stowage brackets for camouflage support poles. A camera mounted above the rear cooling air outlet is connected to a monitor on the driver's dashboard to enable him to reverse at high speed, without needing directions for the commander. The road wheels are now made of steel, replacing those made of aluminium.

The turret front and sides are fitted with wedge-shaped add-on armor in sections, which can easily be replaced by field workshops if hit or, at a later stage, be replaced by more advanced armor. The side panels of this extra armor are hinged to swing forward, neccessary when engine is to be replaced. The gun mantlet was completely redesigned, and additional stowage boxes are fitted to the turret rear and sides. The interior of the turret is now fitted with a spall liner for improved protection against splinters. The electro-hydraulic gun control and stabilization system was replaced by an all-electric system. The optical FERO Z-18 auxiliary telescope was relocated to a position on top of the gun mantlet, and the commander's PERI-R 17 panoramic sight has been moved to the left rear of the commander's station. The commander's improved independent sight now includes a thermal channel whose image is displayed on a monitor on the commander's station. The laser range data processor was modified so that the Leopard 2 A5 can now engage helicopters with APFSDS-T ammunition, and a GPS vehicle navigation system is built in with the GPS antenna installed at the rear of the turret roof.

The additional armor has increased the combat weight of the Leopard 2 A5 to 59,500 kg, which has not affected the mobility, as the vehicle was designed to accept such an increase.

|

| Leopard 2A6, heavily camouflaged, of the German Bundeswehr, on maneuvers. Photo: Krauss-Maffei Wegmann GmbH & Co. KG |

The Leopard 2 A6

The Leopard 2A6 includes a longer L55 gun, an auxiliary engine, improved mine protection and an air-conditioning system. The German Army is upgrading 225 2A5 tanks to 2A6 configuration, the first of which was delivered in March 2001. The Royal Netherlands Army has ordered the upgrade of 180 of its 2A5 tanks to 2A6 configuration, the first of which entered service in February 2003.

In March 2003, the Hellenic Army of Greece ordered 170 Leopard 2 HEL (a version of the 2A6EX) for delivery between 2006 and 2009.

The Leopard 2E, of the Spanish Army, showing the extra armor on the front hull, and the new 120mm L55 gun.

Spain has ordered 219 Leopard 2E (a version of the Leopard 2A6 with greater armor protection) and 16 Leopard 2ER recovery vehicles, and four Leopard 2 driver training vehicles. The first 30 are being built by Krauss-Maffei Wegmann GmbH, and the rest will by licence-built in Spain by General Dynamics, Santa Barbara Sistemas (GDSBS). Deliveries of the first batch began in 2004 and should complete in 2008.

Leopard 2E, showing the full 130 cm increase in barrel length of the new 120mm L55 gun.

(Photo: Circulo Trubia.)

The Spanish version has some changes compared to basic A6 model beside more armor, including an Indra/KAE LINCE C2 system, Indra 2nd gen TI for gunner and TC, a new Indra 3rd gen passive scope for the driver and Spanish PR4GE (license built 2ng gen PR4G digital frequency hopping radios) with data modem for wireless secure data transmission.

Firepower

The Leopard 2E - of the Spanish Army - firing the new 120mm L/55 gun.

A new smoothbore gun, the 120 millimeter L55 Gun, has been developed by Rheinmetall GmbH of Ratingen, Germany to replace the shorter 120 millimeter L44 smoothbore tank gun on the Leopard 2.

The 120 millimeter L44 gun barrel has a length of 530 cm and weighs 1,190 kg. The whole gun weighs 3,780 kg. By comparison, the 120 millimeter L55 gun barrel has a length of 660 cm and weighs 1,374 kg. The whole L55 gun weighs 4,160 kg. The extension of the barrel length from caliber length 44 to caliber length 55 (130 cm) results in a greater portion of the available energy in the barrel to be converted into projectile velocity.

An important characteristic of the new L55 gun is its compatibility with the Leopard 2 weapons system, meaning that it can be integrated without substantial alterations. The external geometry of the gun was designed to minimize the phenomenon of static sagging, as well as to achieve optimum constant curvature. With respect to both of these factors, the form of the barrel selected for the L55 plays a critical role. This was a prerequisite for the system's high first-shot hit probability. The L55 gun can fire any standard 120 mm round.

Especially when using the new DM 53 KE round, the L55 enables approximately an 30 percent increase in performance compared with conventional systems. For example, when fired from the longer barrel, the DM 53 (LKE II) KE round attains a muzzle velocity in excess of 1,750 m/s.

The L55 smoothbore gun, equipped with a thermal sleeve, a fume extractor and a muzzle reference system, is compatible with current 120mm ammunition and new high penetration ammunition.

An improved kinetic energy ammunition known as LKE II was developed as a result of a Tactical Requirement issued in November 1987, and uses the longer gun barrel. The effect of the kinetic energy projectile on an enemy target is achieved by 1) the penetrator length and projectile mass and the impact velocity and 2) the interaction between the projectile and the target. The penetrator material is heavy tungsten powder in a monoblock structure. The improved kinetic energy ammunition has higher muzzle energy and recoil forces.

Rheinmetall's latest ammunition developments for the Leopard 2 include the DM 43 A1 120mm KE cartridge, DM 53 120mm LKE cartridge and the new 120 MP cartridge.

The Leopard 2 A6 lethality effectiveness is especially due to the development, by Rheinmetall W & M, of a smoothbore gun system. Based on the military requirement for firepower enhancement, Rheinmetall W & M further improved the performance of this gun and pertaining KE-ammunition. A 130 cm increase in barrel length plus other modifications (the chamber can support higher pressure from new propellants) resulted in a higher projectile velocity and increased KE-performance. Estimated muzzle kinetic energy, firing the APFSDS DM 53 (LKE II) round, is around 18-20 megajoules (MJ). The 120 mm L55 weapon is compatible with the current MBT-types in service throughout NATO, as they can easily be retrofitted.

| The New Rheinmetall 120mm L55 Gun: |

|---|

|

| The 120 mm L55 hyper-velocity gun: a 130 cm increase in barrel length plus other modifications resulted in a higher projectile velocity and increased KE-performance. |

A further performance increase of the Leopard 2A6 was achieved by the introduction of the DM 53 (LKE II) tungsten long rod penetrator round. This round has a significantly higher penetrating capability than other current types of KE-rounds and is considered a guideline when equipping current or future systems. Estimated penetration performance of the DM 53 (LKE II) tungsten long rod penetrator round fired by the Rheimetall 120mm L55: 750 mm at 2000 meters.

The secondary target spectrum is covered by the other ultra-modern secondary rounds (HE and MP).

Protection

|

| The Leopard 2A6, despite all weight gain (from Military Loading Class 60 to 70 tons) due to repeated armor protection upgrades, plus the new 120mm L55 gun, retains all the traditional maneuverability of this MBT series. Above, a Leopard 2A6 demonstrates the MBT's capability to cross a small river. |

The Leopard 2 A6 is protected by third generation composite armor, with the additional reinforcement to the turret frontal and lateral armor with externally mounted add-on armor modules. In the event of weapon penetration through the armour, a spall liner reduces the number of fragments and narrows the fragment cone. The spall liner also provides noise and thermal insulation. The reinforcement provides protection against multiple strike, kinetic energy rounds and shaped charges.

The charts below show the armor protection improvements implemented on the last Leopard 2 models:

| Leopard 2 A4 MBT - Estimated Armor Protection Levels (Late 1990's) | ||

|---|---|---|

Leopard 2 A4 |

Against Kinetic Energy |

Against Chemical Energy (in mm of RHAe) |

| Turret | 590 - 690 |

810 - 1,290 |

| Glacis | 600 |

710 |

| Lower Front Hull | 600 |

710 |

| RHAe = Rolled Homogeneous Armor Equivalent; an equivalent RHA thickness of a given armor type against a given armor piercing ammunition or missile (i.e. Kinetic Energy penetrators, like APFSDS DU long-rod penetrators or Chemical Energy projectiles, like HEAT ammunition and ATGM's). Modern composite (Chobham) armor may be several times more efficient against Chemical Energy than RHA of the same thickness. | ||

| Source: Tank Protection Levels web site. | ||

| Leopard 2 A5-A6 MBT - Estimated Armor Protection Levels (2002 - 2004) | ||

|---|---|---|

Leopard 2 A5 - A6 |

Against Kinetic Energy (in mm of RHAe) |

Against Chemical Energy (in mm of RHAe) |

| Turret | 920 - 940 |

1,730 - 1,960 |

| Glacis | 620 |

750 |

| Lower Front Hull | 620 |

750 |

| RHAe = Rolled Homogeneous Armor Equivalent; an equivalent RHA thickness of a given armor type against a given armor piercing ammunition or missile (i.e. Kinetic Energy penetrators, like APFSDS DU long-rod penetrators or Chemical Energy projectiles, like HEAT ammunition and ATGM's). Modern composite (Chobham) armor may be several times more efficient against Chemical Energy than RHA of the same thickness. | ||

| Source: Tank Protection Levels web site. | ||

The Leopard 2 A6 is one of the best protected main battle tanks in the world, standing in the same class as the US M1A2 SEP Abrams.

The new Leopard 2A7+, presented by KMW on July 14, 2010 as a new generation of one of the most successful main battle tank designs in history, incorporates a modular protection kit, increased mobility, improved sustainability, enhanced reconnaissance abilities and an even more precise deployment of its various weapons.

The Leopard 2A7+ is an upgraded Leopard 2A6 armed with the Rheinmetall 120mm L/55 smoothbore gun. It is also possible to upgrade the Leopard 2A4 or Leopard 2A5 with the older Rheinmetall 120mm L/44 gun to the latest Leopard 2A7+ standard.

The new MBT, which was tested and approved by the German Bundeswehr (which is expected to upgrade at least part of its fleet of 225 Leopard 2A6 and 125 Leopard 2A5 to this standard, funds permitting), brings to the scene a new concept in modularity, providing a weapons system that actually allows operations in urban terrain as well as high intensity operations.

Next to the unmatched IED and mine protection, the modular protection concept allows for additional passive armor over the frontal arc, as well as along the sides of the hull and turret, plus the integration of an urban operations kit that also offers a 360 degrees protection against RPG's.

Target oriented firepower

The capability to fire the new programmable 120mm HE-round (for the Rheinmetall 120mm L/55 smoothbore gun) enables the crew to engage targets behind cover and within buildings. Fitted with KMW’s FLW 200 Remote Controlled Weapon Station (RCWS) armed with a .50 MG and 76mm grenade launchers, which is operable under protection, the LEOAPRD 2 A7+ is assertive in both built-up and non-built-up terrain.

Increased mobility

The LEOPARD 2 A7+ benefits from an increased mobility by a newly developed final drive, a new track, enhanced torsion bars, an improved brake-system and an adaptable dozer blade to clear obstacles for following vehicles.

Enhanced sustainability

Furthermore it is equipped with a high-performance cooling unit and an APU (auxiliary power unit) to accomplish a 24-hour battle day. The redesigned operational concept allows the crew to utilize the new capabilities efficiently.

Leopard 2A7: Outstanding performance in either urban or high-intensity operations.

(Photo: Krauss-Maffei Wegmann GmbH & Co. KG.)

Enhanced reconnaissance and situational awareness

The commander and gunner benefit from the 3rd generation ATTICA™ thermal sight, near field surveillance at day and night as well as day and night cameras for the driver.

Tank damaged – crew alive

The Canadian Army uses the LEOPARD 2A6M in Afghanistan. This version corresponds to the A6 version, but it also has enhanced protection against mines and booby traps. The fact that this protection is extremely effective was demonstrated in November 2007. Taliban fighters carried out an attack on a Canadian Leopard 2A6M-CAN with a large booby trap. The tank was indeed damaged, but the entire crew survived the attack. Following a repair the Leopard 2A6M-CAN is now back in use once again.

LEOPARD 2 IN FOREIGN SERVICE

Leopard 2A6M CAN: Canadian Leopard 2A6M, adapted to meet the requirements of the Canadian Forces. The tank has add-on front armor, and slat armor is installed. Leopard 2A6M is a state of the art model, that includes an integrated mine protection, with increased armor on and under the lower front hull, and the underbelly, plus a new redesigned crew compartment, which increases survivability. The 20 Leopard 2A6M CAN, delivered on August, 2007, were loaned by the Canadian Forces from Germany, to increase the effectiveness of Canadian units deployed in Afghanistan. Canada will also buy 100 Leopard 2A4 tanks, as a result of a government-to-government agreement between the Netherlands and Canadian governments. This acquisition will meet the long-term requirements of the Canadian Forces.

Leopard 2A4, 41(NL) Tankbataljon, 41(NL) Lichte Brigade, Weser-Emsland, June 1993.

Swiss Pz87 : The Pz 87 Leopard 2 differs from its German counterpart in having a slightly altered turret rear, with a slope at the rear left side, and an additional stowage box for the camouflage net on the right turret rear. On the left turret rear is a box containing the external head-set connection for the crew's intercomm. Swiss-made WF Bern 7.5 mm MG 87 machine guns are installed, one mounted co-axially to the main gun, and one fitted to the loader's station on a Swiss-built MG mount for air-defense. AN/VCR 12 radios of US design, produced under license, are installed. On the left and right sides of the turret, next to the Nebelwerfer 87 smoke mortars, are two tubular cases for interim storage of hot exchanged machine guns barrels. Three grousers are stowed on the left turret side and a further seven on the right, which with the 18 carried on the bow brings the total to 28 grousers for use on soft or snowy ground instead of the same number of rubber track pads. Switzerland introduced the extra noise-reducing exhaust mufflers, attached to the vehicle's rear, for its entire fleet of KPz 87. All Pz87 carry the standard German camouflage scheme. Switzerland participated in the tri-lateral KWS II improvement program, and so will upgrade its Pz87 to the Leopard 2 A5 in the next century.

Dutch Leopard 2 : The Leopard 2 NL differs from its German counterpart in having a Dutch-designed smoke mortar system with six barrels on each side, a Dutch-built passive night periscope for the driver, a 7.62 mm FN MAG machine gun installed co-axially to the main gun and one further MAG for air defense, and Philips radios with US-style antenna bases. In January 1993, the Royal Netherlands Army announced plans to phase out 115 of its 445 Leopard 2 NL, which were sold to Austria, and to upgrade the remaining 330 vehicles to the standard of the German Leopard 2 A5. The first improved Leopard 2 NL were delivered to the Royal Netherlands Army in May 1997. These vehicles use the same German camouflage scheme, but retain the Dutch radios, antenna bases, FN MAG machine guns and smoke mortars. The Royal Netherlands Army has ordered the upgrade of 180 of its 2A5 tanks to 2A6 configuration, the first of which entered service in February 2003.

Leopard 2A5/Leopard 2 (Improved) : Upgrade with spaced armor added to turret front, and increased armor on hull and side skirts. Other improvements include improved stabilization, suspension, navigation, fire control, and hatch design.

|

| The Leopard 2E, of the Spanish Army. |

Leopard 2E : A derivative of the version 2A6 (with greater armor protection), developed under a program of co manufacture between the industries of Spain and Germany. The program is developed within the frame of collaboration decided in 1995 between the Ministries of Defense of both countries, in which also was included the cession of use by a period of five years of 108 Leopard 2A4 from the German Army to the Spanish Army. However, this cession was extended up to 2016, and after that those tanks will be of the Spanish Army. In 1998, the Spanish government agreed to contract 219 tanks of the Leopard 2E line, 16 recovery tanks (CREC) and 4 training vehicles. They choose Santa Bárbara Sistemas as the main contractor. The program, with a budget of 1,939.4 million Euros, includes also the integrated logistical support, training courses for crew instructors and maintenance engineers and driving, tower, maintenance, aiming and shooting simulators. The first 30 Leopard 2E are being built by KMW and the rest will be license-built in Spain by General Dynamics, Santa Barbara Sistemas (GDSBS). Deliveries of the first batch began in 2004 and should complete in 2008.

Stridsvagn (Strv) 121 : In 1994 and 1995 a total of 160 Leopards 2 A4 of the first five batches, taken from the German stocks were delivered to the Swedish Army. Officially designated the Stridsvagn 121, the first vehicle arrived in Sweden in February 1994. There were no noticeable changes or modifications carried out to these vehicles, used by the Swedish mechanized brigades.

|

| The Stridsvagn (Strv) 122. |

Stridsvagn (Strv) 122 :

The Swedish Defense Materiel Administration (FMV) signed

a contract with Krauss-Maffei for the manufacture and delivery

of 120 Leopard 2-S officially designated as the Stridsvagn

122 by the Swedish Army. The contract also includes the

supply of training, maintenance, spare parts, documentation,

simulators, and an option to purchase 90 additional Strv

122, Bueffel ARV as well as interfaces for equipment already

used by the Swedish Army. While Krauss-Maffei is the prime

contractor, the chassis was sub-contracted to Hägglunds

in Sweden. Wegmann, the prime contractor for the turret,

sub-contracted the work to Bofors, and work for the fire

control system was sub-contracted from STN Atlas Elektronik

(formerly Krupp Atlas Elektronik, KAE) to Celsius Tech

Systems AB in Sweden. Bofors will also manufacture 50 per

cent of the 120 mm main guns, while Rheinmetall will produce

the other half.

The Stridsvagn 122 is one of the most sophisticated versions of the Leopard 2 in current service. The front hull and glacis are fitted with additional armor plates, and the inside of the tank is completely surrounded by liner, to reduce the effects of being hit by projectiles, hollow charges or fragments. For night driving the driver uses the same type of passive night sight used by the CV 90 Infantry Fighting Vehicle. Due to the heavier combat weight of 62,000 kg, compared to the 59,500 kg of the German Leopard 2 A5, stronger torsion bars (derived from the ones used with the Panzerhaubitze 2000) are installed and reinforced brake disks are provided. All fuel tanks have a special additional explosion-supressing filling liquid. The engine compartment is constantly cooled to reduce the IR signature, and heat sensors installed in the engine compartment would automatically cut off fan and air intake operation if the Strv 122 should come under attack by napalm. the roadwheels are fitted with armored wheel hubs.

The turret front and sides have the same wedge-shaped add-on armor as the Leopard 2 A5 but, unlike the latter, the turret roof and the commander's and loader's hatches are also up-armored. Due to the extra weight, both turret hatches were of the electrically-driven sliding type, but this was abandoned because of the problem of opening the hatches if there was a power out. Now the turret hatches are handcrancked with a gear, so its no problem to operate them even if the tank is in a bad angle. The commander's periscope has an manually operated protective flap, which would fold up to protect the optic when desired and rests in front of it when not in use. The digital fire control computer carries data for up to 12 different rounds, including APFSDS-T, HEAT-MP-T, HEAT-GP, smoke, anti-helicopter and training ammunition. However, at the time this is being written (August, 2001), only five types of ammunition are being used: 120mm APFSDS-T, 120mm HE-T, 25mm APFSDS-T, 25mm HE, and 120 mm TPFSDS-T. The 25mm is for a barrel insert system, and used for basic training on closer fire ranges. Smoke, HEAT and helicopter rounds are not in use. The helicopter round is under development.

The laser rangefinder integrated in the EMES-15 uses the eye-safe Raman-shifted laser. The Strv 122 is the first MBT in Europe equipped with the advanced tank command and control system (TCCS). On the left and right sides of the turret the GIAT Industries GALIX vehicle protection system with 80 mm calibre mortars is installed, able to launch smoke, decoy, flare and fragmentation rounds. There are 36 grousers (snowgrips), 18 for each track, for use on soft ground instead of the same number of rubber track pads.There are 18 grousers stored on the back of the turret and 18 are stored inside the left turret. The Stridsvagn 122 is painted in a disruptive camouflage scheme of green, light green, and black colors.

The new Stridsvagn 122B : During the years of 1997 to 2002, Leopard 2-S MBTs, called Strv. 122 in Sweden, were being delivered to the Swedish Armed Forces. The originally German tank is one of the world's most powerful war machines but after carrying out a few tests, FMV ( Försvarets Materielverk - Swedish Defense Materiel Administration; Procurement Agency for the Swedish Armed Forces) found the tank was lacking in some areas when it came to protection. With the intent to fill up this gap, FMV carried out tests in order to find out how protected the tank was underneath. The results weren't satisfactory and FMV contacted its German equivalent and started the discussion of the problem. Within shortly, Switzerland and Holland were also interested. The goal was to develop a mine protection package for better chances of crew survival.

As a result, a new project was started, where Sweden's area of responsibility was verification and validation, which involved setting requirements and making sure they are met. Holland took care of computer simulation, with animations and calculating forces. Switzerland's role was to made sure the ergonomics and other requirements were being met after the modifications. Germany responsibility was to lead the project's group.

In order to have a fully-functional mine protection, several modifications to the original MBT were needed. The basic requirement was that it would protect the crew from reasonably-sized pressure-activated mines as well as those that use shaped charges designed to penetrate armor. The goal was not only to have the crew survive a blast, but also to be able to successfully get out of the vehicle afterwards.

The primary concern was to protect the driver's seat. The solution was a 'web' design made from fabric and is actually worn on the body, similar to a parachute. All the driver need to do once he is using it on is hook himself to the six belts which have been fitted in the driver's compartment. The basic principle is that the driver should have no contact at all with the floor of the tank. Even though the floor and bottom are reinforced with the new armor plate specifically designed to protect against mines, the risk of injury or death could not be eliminated if the driver's seat have kept bolted to the floor. The other modifications are not as evident as this one, but together they help form a safer work environment for the crew.

This new mine protection kit is being offered by Krauss Maffei Wegmann. Even though five countries have split the costs of the project, so far only Sweden and Germany have carried out the modifications on part of its Leopard 2 fleet. Germany has purchased 70 units while Sweden has purchased 10 units. Today the modified Strv. 122s, designated Strv. 122B, stand ready to participate in international missions and in the future Nordic Battle Group. A cost-effective and successful project was implemented.

Austrian Leopard 2 : In 1997 Austria purchased 115 Leopard 2 formerly used by and phased out by the Royal Netherlands Army.

Danish Leopard 2 : In July 1997 a contract was signed between Danish officials and Krauss-Maffei for the delivery of 52 Leopard 2 A4 from German stocks. By 29th of June 2000 the Danish Army Command signed a contract with Krauss-Maffei Wegmann, concerning the upgrade of 51 Leopard 2 A4 to Leopard 2 A5 DK standard. The project is worth 855 mill. DKr. The tanks are to be part of The Danish Reaction Brigade. The A5 are expected to be operative until 2025. The first A5 was handed over to the Army Material Command on the 24th of September 2002. The requirement was that the new Leopard 2 A5 DK should be of the standard of Leopard 1 A5 DK (SFOR). The configuration is based on the German/Dutch "Mannheimer-configuration" and the improvements made on the Swedish S 122. The upgraded Leopard 2 A5 DK will be equal to the German/Dutch Leopard 2 A5 with the specific purpose of being able to share training, logistical and technical expertise with other users of Leopard 2 A5.

The Danish Leopard 2 A5 will have more improvements than the German/Dutch tanks, and will use the improvements made with the Leopard 1 A5 DK (SFOR). Key elements of the upgrade are: - Improvement of the passive protection of the crew and the tank. - Improvement of the TC's working environment and his possibilities of using the tank in different circumstances. - Technical upgrading as required when adding/replacing armor. - Arrangements to ensure future upgrading of the tank. - Other improvements. Passive protection: - The Leopard 2 A4 configuration with the main and secondary sights are closed with new armor-modules. The gun mantlet was made narrower to make room for the armored modules which are placed on the front of the turret and the forward part of the sides of the turret. - On the hull, the existing composite armor are replaced with improved composite armor and additional armor are placed on the front.

The skirts are replaced with a new type. The drivers hatch are replaced with a new hatch which will be somewhat heavier. The new type of hatch will be a slide-type of hatch. The bearings of the road wheels will be of a new type witch are armored. On the inside both turret and hull will be fitted with spall-liners to protect against fragments. The protection of the hull differs from the Mannheimer-configuration where there are no replacements of the armor in the hull. This is manly due to the late batch of hulls where the protection is somewhat better than the hulls of the Danish Leopard 2 A4. Further improvements - Leopard 2A5 DK : Due to the increased weight of the turret and the lessons learnt during the Gulf War the Leopard 2 A5 DK are fitted with a 100% electrical system for turning the turret, stabilizing the gun etc. The system is capable of supporting a latter upgrade of the gun to 120 mm L55 or a 140 mm gun, and an additional armor on the top of the turret. - The angulated head of the gunners primary sight will be moved on to the top of the turret. The TC will be able to see the gunners sight on a monitor through the Charge-Coupled-Device (CCD).

The secondary sight of the gunner will be moved as to make it possible to put additional armor on the front of the turret, as mention above. - The commanders sight are moved to the rear of his cupola and will be fitted with stabilized sight with both daylight and thermal sights. The sights will be delivered by Elop Electro-Optics Industries, a subsidiary to Elbit Systems Ltd.in Israel. The contract is worth $3 million and runs over a period of two years. - The weight of the tank will increase to around 61 tons (MLC 70) instead of the 55 tons (MLC 60). - The tank will be fitted with an hybrid-navigational system based on the GPS-system, backed up by an inertial navigational system. The system will be prepared for future identification systems. - On the rear of the tank a camera will be mounted, witch will enable the driver to back up without the aid of the TC (only in daylight or twilight). - The cooling air of the engine are rerouted so as to ensure a further low thermal signature with no cooling are to be wended to the sides only in the back of the tank. - Furthermore the vehicle will be fitted with an electrical generator to help keeping the cooling system (air-condition and turret) with electricity.

Also, this will enable the tank to be fitted with some kind of battlefield management system in the future. - As mention above the tank will have an air-conditioning system, and an explosion suppression system. The engine compartment will be protected a fully automated system to protect against napalm. - The fuel tanks are protected against explosions as with the Leopard 1 A5 DK (SFOR). The upgrading will take place in Munich (hull) and Kassel (turret). Source: Danish Army Vehicles Homepage. By November 2002, 18 Leopard 2A5 DK were ready for test and training. The Danish Army should have all its MBT units equipped with the new Leopard 2A5 DK by 2025. (Special thanks to Thomas Dysted for the update!)

|

| The latest version of the Leopard MBT is the Leopard 2 A6 EX. (Photo: Krauss-Maffei Wegmann GmbH & Co. KG.) |

Leopard 2 A6 (EX): As its newest Leopard 2 variant, KMW is presenting the Leopard 2 A6 EX MBT, which includes the longer L/55 gun, an auxiliary engine, improved mine protection and an air-conditioning system. Superior firepower is guaranteed by the 120 mm smooth-bore gun of the Leopard 2 A6 EX. The development of the L/55 gun, a more powerful, longer version of the main armament and newly developed types of ammunition provide better penetrating power and permit target engagement at longer ranges. The German Army is upgrading 225 Leopard 2A5 tanks to the A6 configuration, the first of which was delivered in March 2001. The Royal Netherlands Army has ordered the upgrade of 180 of its Leopard 2A5 tanks to the A6 configuration, the first of which entered service in February 2003.

|

| Leopard 2HEL, of the Hellenic Army of Greece - as a variant of the Leopard 2A6, this Main Battle Tank is also equipped with the new Rheimetall 120mm L55 gun. |

Leopard 2HEL (Hellenic): In March 2002, the Hellenic Army of Greece announced that it had selected the Leopard 2 GR (a variation of the Leopard 2 A6), with a requirement for 170 tanks, to be delivered between 2006 and 2009, as well as the aquisition of 183 Leopard 2A4, from the Bundeswehr. The first units of the Leopard 2HEL were delivered in March, 2006.

Other countries using Leopard 2 tanks: The Norwegian Army bought 52 used Leopard 2A4 MBT's from the Dutch Army. The agreement was signed February 8 2001 and is worth 1,5 billion NOK. The first tanks was delivered in December 2001. The German produced tanks were build for the Dutch Army from 1983 to 1985, and have been slightly used (Source: Scandinavian Armor Website).

The Finnish Army is buying 124 and the Polish Army 128 used Leopard 2A4 tanks from Germany.

In connection with the transfer to Turkey of 298 surplus Leopard 2 main battle tanks from the Bundeswehr inventory, Rheimetall Defence received an order in December 2005 to supply Turkey with some 15,000 rounds of 120 mm KE ammunition (the DM 63, including practice ammunition). The order is worth around EUR 46 million. Delivery will take place during period July 2006 to June 2007 (Source: Rheinmetall DeTec AG).

LEOPARD 2 - VARIANTS

The Driver Training Tank (Fahrschulpanzer)

In addition to theoretical education and simulator driving, the Bundeswehr

uses 31 Leopard 2 training tanks, which were delivered in two batches.The first

batch of 22 vehicles, of which eight were built by Krauss-Maffei and 14 by

Mak (chassis nbr. 19001 to 19022), was delivered between February and September

1986. The chassis were taken from current production and are therefore equivalent

to those of the fifth batch. The second batch of nine vehicles, of which five

were built by Krauss-Maffei and four by Mak (chassis nbr. 19023 to 19031),

were delivered between January and April 1989; their chassis are equivalent

to the sixth batch with the new side skirt forward sections.The driver training

tank is essentially a regular Leopard 2 MBT with its turret replaced by a special

observation cabin, with a dummy gun and extra weight to simulate that of an

MBT turret.The instructor, with appropriate devices to override the trainee

driver seated in the hull, sits in the front seat of the observation cabin.

Two additional seats in the "glasshouse" provide space for pupils

to observe. The Netherlands have 20 driver training tanks in operation, Switzerland

uses three, and the Spanish Army uses four (info courtesy of Fernando

Albarracin).

Bergepanzer 3 'Bueffel'

ARV

The first component studies for a new armored recovery

vehicle (ARV), planned to the maintenance support

for the new Leopard 2 which was soon to enter service,

began in 1977. On the introduction of the Leopard

2 it soon became apparent that the Bergepanzer 2

A2 ARV (based on the Leopard 1 chassis) would not

be powerful enough to provide adequate maintenance

support under 24 hour combat conditions, so a development

program for a new ARV was launched.

The first experimental vehicle with a similar layout

to th Bergepanzer 2 A2 and a wooden mock-up for an

alternative internal lay-out, were ready in 1986.

Two prototypes were ordered in 1987 and the experimental

vehicle built up to the prototypes standard. The

three prototypes were delivered in 1988 and underwent

intensive tests, and in 1990 an order was placed

for 75 Bergepanzer 3 'Bueffel' (Buffalo) ARV for

the Bundeswehr and 25 Bergingstank 600 kN Bueffel

for the Royal Netherlands Army (RNLA).

MaK Systemgesellschaft mbH in Kiel was selected as the main contractor. Production was shared between MaK, with 55 vehicles built, and Krauss-Maffei, with 45 built.

The Bergepanzer 3 Bueffel armored recovery vehicle is based on the chassis of the Leopard 2. The driver sits on the superstructure front with the commander behind him. Three large doors provide access to the inside of the vehicle. A fire extinguishing and suppression system, an NBC protection system, and deep fording equipment with bilge pumps are provided. For night driving the driver can replace one of his periscopes with a passive night sight. During peacetime the Bergepanzer 3 is operated by a crew of two, although space for a third crew member is provided. The engine compartment is at the rear, and the Bueffel uses the same powerpack of the Leopard 2.

A large crane, with a lifting capacity of 30,000 kg. is installed at the right forward of the vehicle, the jib can be traversed 270 degrees. The crane has an electronic momentum limiter, which constantly calculates jib elevation, vehicle tilt, and load mass to prevent overloading. A Rotzler Treibmatic TR 650/3 winch is installed in the vehicle's forward section with an effective cable length of 180 m (33 mm in diameter) and the capacity to pull up to 35,000 kg, which can be doubled by using a pulley tackle.

A complete powerpack can be carried in a special cradle on the engine deck. The large dozer/support blade at the front is lowered as a support to stabilize the ARV during winching or crane operation. The blade can also be used for obstacle and clearence or dozing operations. The Bueffel is equipped with a suspension lockout system. Electrical cutting and welding equipment is also provided. Further equipment includes various couplings and towbars, rapid connect and disconnect couplings for towing, and a self-recovery system. Armament consist of a 7.62 mm MG3 machine gun, primarily used for air defense, and 16 70 mm smoke mortars, with eight fitted in two groups of four at the front and eight in a row at the rear of the vehicle.

Combat weight is 54,000 kg and the Bueffel has a towing capacity of 62,000 kg (MLC 70). Maximum achievable speed is 68 km/h, and 30 km/h in 2nd reverse gear. With a fuel capacity of 1,629 litres, the Bueffel has a maximum range of 650 km on roads and 325 km on across country. The Bueffel is capable of changing the powerpack of a Leopard 2 A4 in about 25 minutes, and with the Leopard 2 A5 about 35 minutes are required. There are 75 Bergepanzer 3 Bueffel being used by the German Bundeswehr, plus 25 in the Netherlands, 14 in Sweden, 16 in Spain, 25 in Switzerland. There more contracts for 12 to Greece, 150 to Korea (where Bergepanzer 3 components - like the crane, dozer/support blade, etc. - are installed on the Korean K1 MBT chassis, resulting in the K1 ARV), 46 to the UAE, and 22 to France (in both the UAE and France cases, Bergapanzer 3 components are installed on the French Leclerc MBT chassis, resulting in the Leclerc ARV).

In addition to these, there is an improved version of the Bergepanzer 3 Bueffel, deveoped for the Swedish Army, the Bgbv 120. This model, in comparison with the armoured recovery vehicle BUFFALO, encompass tactical as well as technical improvements. The Swedish armoured recovery vehicle is provided with an improved ballistic protection including an integrated interior liner protection, a reduced IR signature, a command and control as well as a navigation system, a new weapon station (2048 HYM) and a GALIX launcher system for self-protection. Furthermore, the vehicle has a recovery system with rear-view camera for recovery operations under armour protection, an increased crane system working range, a 1.5 t auxiliary winch and an increased tripple pull performance of the main winch (35 t single pull). After intensive and successful trials with the German armoured recovery vehicle BUFFALO in Sweden, the company was awarded the contract for the manufacture of 14 vehicles for Sweden. Source: Rheinmetall DeTec AG.

|

| The Bueffel is capable of lifting 30,000 kg. and change the Leopard 2A5 powerpack within 35 minutes. (Photo: Krauss-Maffei Wegmann GmbH & Co. KG). |

Leguan Modular Bridge System (Panzerschnellbrücke

2) on Leopard 2

The Modular Bridge System (PSB2), developed for the Netherlands and German

Armies, holds three bridges/bridge modules of 9.7 meters each. This enables

the laying of several different combinations of bridges: 3 x 9.7 meters;

1 x 9.7 meters, 1 x 18.7 meters; and 1 x 27.7 meters. With a crew of one

driver and one operator the bridges can be laid in approximately 3, 5 and

6 minutes respectively. The bridge modules are 4m wide, 0.65m in height and

weigh 5000kg each. Carrying capacity allows for MLC 70 Standard Load (tracked

vehicles) and MLC 100 Caution Crossing (wheeled vehicles). There are contracts

of 35 vehicles for the German Bundeswehr and 14 for the Netherlands.

|

| The Leguan Modular Bridge System (Panzerschnellbrücke 2), with the 3 x 9.7 meters bridges combination. (Photo: MAN Mobile Bridges GmbH ). |

Main performance specifications for the new PSB 2 armoured vehicle launched bridge / Bruglegger MLC70 for the German/Dutch armed forces:

1. Military load class MLC 70/100 for the bridge

2. Modular bridge system, comprising three bridge modules @ 9.7 m

Bridge combinations of 3 x 9.7 m; 1 x 9.7 m plus 1 x 18.7 m; 1 x 27.7 m

3. Launching under armoured protection

4. Horizontal launching

5. Launching times from 5 min (short-span bridge) to around 10 min (long-span bridge)

6. Interoperability with allied armed forces

7. Same protection and mobility as Leopard II A 5 main battle tank

8. Classification of the overall system in military load class MLC 70

9. Service life of 30 years, including 10000 crossings and 3000 launchings

10. Modern reconnaissance and guidance systems

Overall technical concept of the PSB2 / Bruglegger MLC 70:

A characteristic feature of the launching equipment is the parallelogram, formed

in its basic position by the laying arm cylinder, laying arm, front arm and

hull components, which can be moved by means of the front arm cylinder. The

launching equipment draws the bridge modules from the rear "bridge magazine"

according to the bridge length required, with the appropriate magazine levels

being accessed by lowering the parallelogram. A rigid connection between two bridge modules

is established automatically by the launching equipment moving the module ends

one against the another. In the process, the deck plate lifters are brought

into the upright position, and at the same time the ramp deck plates are raised

to their coupling and service position. A crucial requirement when establishing

the concept for the launching equipment was to optimize the system with regard

to the launching times for the cases of use that, statistically, occur most

frequently, in other words the launching of short-span bridges. For these cases

only the vehicle supports are needed.

|

| A Leopard 2A4 main battle tank over the Panzerschnellbrücke 2 (MLC 70). Photo: Bundeswehr. |

The main support system has to be activated solely when launching medium - and long-span bridges. The detachment of the bridges from the launching equipment takes place similar to the method used for the Biber armored vehicle launched bridge, i.e. by disengaging the roller carriages from the bridge rail. Source: Armed Forces International web site.

Panzerschnellbrücke 2

Technical data:

Total weight: 62,5 t

Height: 3,95 m

Width: 4,0 m

Length with bridge: 13,89 m

Crew: 2 men

Bridge: Bridge weight 3 x 5.040 kg

The Panzerschnellbrücke 2 - Leguan Modular Bridge System.

Special Thanks to: Fernando Albarracin.

Leopard 2 AEV (Pionierpanzer 3 Kodiak).

The Pionierpanzer 3 (PiPz 3) Kodiak is a newly developed armored

combat engineer vehicle which meets the increased requirements of modern armed forces

through enhanced effectiveness and functionality. It combines ultramodern combat engineer-specific

technology with the proven components of the Leopard 2 Main Battle Tank.

Mission:

- Building and removal of obstacles;

- Mine breaching;

- Relief missions and missions in disaster areas.

Market:

- Switzerland;

- Potential with all Leopard 2 MBT users.

Main features:

Leopard 2 MBT chassis;

Hinged excavator in center position;

Tiltable dozer system with adjustable cutting angle;

2 x 9 t capstan winch (double quadruple link up to 62 t);

Mine breaching (or mine clearing) kit;

Military Loading Class 70 (MLC 70).

Technical data:

Length: 10.20 meters.

Width: 3.54 meters.

Height: 2.30 meters.

Source: Rheinmetall DeTec AG.

Pionierpanzer 3 Kodiak with mine-plough. Photo: Swiss Army.

The Pionierpanzer 3 Kodiak can also de used as minefield clearing armored vehicle, as the dozer blade can be changed for a full-width mine plough. Whatever configuration is used (for instance, the inclusion of anti-mine protection devices) the Pionierpanzer 3 is guaranteed to stay within the weight limits of the Military Loading Class 70 (MLC 70).

Since the prototype rolled out in autumn 2003, the system has already been tested by Switzerland, the Netherlands and Denmark. Additional trials, for example in Sweden, are currently under preparation. A number of nations are already considering procuring the AEV Kodiak, and the consortium is looking forward to signing the first full-scale production contract in the near future.

The Panzerpionier 3 Kodiak provides combat engineers with a multifunctional tool not unlike the famous "Swiss Army Knife": based on a Leopard 2 chassis (including anti-mine protection), the Kodiak is equipped with a hinged excavator, two capstan winches and a tiltable dozer blade which can be exchanged for a mine plough.

The Kodiak is also very useful off the battlefield, for example in disaster relief operations following hurricanes, earthquakes or floods, as well as in post-conflict reconstruction scenarios. Source: Rheinmetall-DeTec AG.

Leopard 2 PSO Technology Demonstrator - New threats call for new responses.

Photo: Krauss-Maffei Wegmann GmbH & Co. KG

The political security situation of the 21st century has changed from what it was. The world is no longer divided into east and west, the German armed forces and their allies in NATO are no longer just there to deal with the war on two fronts and the potential enemy has become militarily unpredictable. Today conflicts are spread around the globe, are usually confined to regions and are often the result of states collapsing politically. The threat does not necessarily come from an army; it could come from organized fundamentalists, terrorists and even from individuals. For peacemaking and peacekeeping deployments, Krauss-Maffei Wegmann is designing the LEOPARD 2 for Peace Support Operations (PSO). Military assertiveness and sustainability, highly mobile and extremely well protected, it is a tank that is also suitable for use against single targets and optimally so in both built-up and non-built-up terrain. KMW will be presenting the first demo LEOPARD 2 PSO - mainly financed from its own funds - at the 2006 Eurosatory.

With the LEOPARD 2 family vehicles, the armed forces of 13 countries are provided with a highly developed system whose capabilities will now be adapted for urban operation and asymmetric threats. The recent conflicts have more than demonstrated how necessary main battle tanks are as a means of escalation and de-escalation. Nevertheless capability gaps have arisen which the LEOPARD 2 PSO will now close. That is why the new LEOPARD 2 variant concentrates on those components that allow it to accomplish assignments in urban areas and asymmetric threats. They include highly effective all-round protection, a secondary weapon station that is operable under protection, an option for equipping with non-lethal effective means, a high-performance camera system for close observation, an enhanced reconnaissance ability, search light and a dozer-blade for barricade removal.

Peacemaking and peacekeeping operations will in future become crucially for the armed forces. The upheavals in eastern Europe globally shifted the power structure and new flashpoints have arisen in our multipolar world. Organized crime, international terrorism and the narcotics trade provide just some examples threatening the safety and security not only of individual regions but also, in the last resort, of the whole world. Thus the armed forces need military capabilities that are adapted to the various needs - particularly in terms of highly intensive simultaneous and close-quarter operations against all armored targets and extending to stabilizing steps and humanitarian aid in the sense of a three block war. The military assertiveness even in urban operations is made possible by high tech equipment and optimum weapon deployment covering the entire assignment spectrum. To this end the LEOPARD 2 - the synonym for cutting-edge main battle tank technology across the world - is adapted to the today's and tomorrows threats.

The idea is for the crew to act independently on the spot and yet be protected to the highest possible degree. The threat is asymmetrical and can come from all sides: anti-tank mines, hand-held weapons, grenades, IEDs (improvised explosive devices) to name just a few. Aside from the extremely high all-round and mine protection system, the LEOPARD 2 PSO therefore has additional components making it highly suitable for deployment in urban areas under all climatic conditions. It has a high-performance cooling unit, APU (auxiliary power unit), modern guiding systems and is equipped for a 24-hour battle day. For optimum observation by day and night, the LEOAPRD 2 PSO is also fitted out with a 360( camera system, the most up-to-date IR equipment and an outside communication point for the infantry.

The visible presence alone of the armed forces in areas being fought over has a stabilizing effect. The requirement for this, however, is having equipment and technology adapted to the deployment scenarios of today and tomorrow. Only then can a quick engagement rapidly stabilize the situation. This requirement is best met by the LEOPARD 2 for peace support operations.

The LEOPARD 2 of the 21st century

For its self-defense, the LEOPARD 2 PSO has a Type FLW 200 weapon station with integrated day and night sights on the turret, which the crew can operate remotely from a monitor in the protected interior. The weapon station has a horizontal traverse of 360°. Up and down, the FLW 200 can be moved in an arc of almost 90° overall. This allows the crew of the LEOPARD 2 PSO to defend themselves on all sides, and to observe and open fire on upper stores of urban buildings. The weapons station can be armed either with various machine-guns (light, medium, heavy) or with 40 mm automatic grenade launchers. But it can also be loaded with non-lethal ammunition, for example to bring a rebellion under control. The hydraulic rake blade, which can be raised, lowered and swiveled left and right, can also be used for this purpose.

With it, the LEOPARD 2 PSO can clear barricades or other obstacles out of the way. A special communication platform at the rear of the tank facilitates cooperation with dismounted infantry personnel. In addition, each LEOPARD 2 PSO is equipped with the IFIS guidance system. The provision of data transmission equipment and a GPS system means that the exact position of each tank is known. This makes guidance in battle easier, and minimizes the risk of firing on friendly units by mistake, because the crew of each LEOPARD 2 PSO knows where their own and the enemy troops are.

The LEOPARD 2 PSO clears the way

In order to maintain a clear overview even in confused situations, the crew can observe the immediate surroundings by means of a high-performance camera system. Monitors give the crew a 360° field of vision around the vehicle. Threats can thus be detected more quickly, and the crew can react immediately. In addition, they have a total of three modern thermal-image units and two search and sighting lights at their disposal for reconnaissance purposes.

A high-performance cooling system ensures that the climate inside the LEOPARD 2 PSO remains in a comfortable range, whether it is hot or cold outside. KMW presented the first prototype of the LEOPARD 2 PSO at the Eurosatory 2006 in Paris. Meanwhile the tank has given impressive proof of its extraordinary mobility as a so-called test carrier. Because of their intense interest in the tank, the Bundeswehr were and still are very closely involved at a conceptual level in its development, which KMW have financed entirely out of their own assets.

KMW also took into consideration the experience of the Canadian and Danish armed forces, which have already successfully deployed the LEOPARD 2 in Afghanistan. The components of the LEOPARD 2 PSO are so designed that all LEOPARD 2s that are at present in use can be upgraded to this version. In the years 2011 to 2018, the Bundeswehr intend to have a total of 150 of their LEOPARD 2s fitted with PSO components. In addition, 50 so-called UrbOp (Urban Operations) kits are to be procured; these also are also based on PSO components. This is the Bundeswehr’s reaction to the changed mission requirements that German soldiers are encountering in their conflict-prevention and crisis-containment missions, including the fight against international terrorism. With the PSO version, KMW, as the partner of the Bundeswehr, are turning the LEOPARD 2 battle tank into a weapon system that is technically fit for the 21st century.

The Leopard PSO thus combines sustainability and efficiency for MOUT (Military-Operations-in-Urban-Terrain) missions - the new range of assignments for the Allied armed forces. Source: Krauss-Maffei Wegmann GmbH & Co. KG.

Press Release 09.14.2006, from Rheinmetall AG

Rheinmetall to supply electronics for Hellenic Army Leopard 2 tanks

The Hellenic Army has contracted with the Düsseldorf-based Rheinmetall Group to supply electronic diagnostic systems for its Leopard 2 main battle tanks as well as command and information systems for battalion command posts. A Group subsidiary, Rheinmetall Defence Electronics of Bremen, will execute the multi-million euro order; delivery of the systems is to be completed by 2008.

The order takes the form of a commissioning agreement issued by Germany's Federal Agency for Defence Technology and Procurement on behalf of the Greek authorities. It is based on a government-to-government agreement between Germany and Greece concerning the sale of 183 surplus Leopard 2 main battle tanks and peripheral systems from the Bundeswehr inventory. Another Group subsidiary, Rheinmetall Landsysteme, has been assigned partial responsibility for servicing the vehicles.

Under the new contract, Rheinmetall Defence Electronics is tasked with supplying the necessary hardware and software as well as tactical and technical integration with the NATO-interoperable Iniochos command and information system through to battalion level.

The package also encompasses an order for diagnostic testing equipment and systems for all levels of maintenance, including the tank's laser rangefinder and thermal imaging devices as well as a complete mobile testing kit for electronic, optical and optronic components. Moreover, Rheinmetall will supply additional technology for the existing depot testing facility at Velestino, Greece.

The system can be used to test the fire control components of a wide cross section of combat vehicles, including the M48 and Leopard 1 as well as Greece's newly acquired Leopard 2.

Thanks to its subsidiary Rheinmetall Defence Electronics, the Rheinmetall Group is one of the world's leading suppliers of network-enabled reconnaissance and command systems as well as fire control technology (Rheinmetall AG).

Press Release 02.15.2006, from Rheinmetall AG

Large-caliber contracts go to Rheinmetall - Turkey and the Netherlands order ammunition worth EUR 79 million.

Turkey and the Netherlands have recently awarded Rheinmetall AG of Düsseldorf contracts for large-caliber ammunition worth some EUR 79 million.

In connection with the transfer to Turkey of 298 surplus Leopard 2 main battle tanks from the Bundeswehr inventory, Rheinmetall Defence received an order in December 2005 to supply Turkey with some 15,000 rounds of 120 mm KE ammunition (the DM 63, including practice ammunition). The order is worth around EUR 46 million. Delivery will take place during period July 2006 to June 2007.

The DM 63 is a tungsten-based kinetic energy round whose new temperature-independent powder also makes it suitable for use in extreme climate zones without limitation.

Coming hard on the heels of the decision of Germany's Bundeswehr - an important Rheinmetall reference customer - to buy the new round in summer 2005, the Turkish order represent an important export breakthrough. Potential customers include the roughly twenty nations whose tanks are equipped with 120 mm main armament technology from Rheinmetall.

In the artillery domain, the Dutch Army's decision to procure Rheinmetall's newly developed Rh 40 DM 131 round also represents a major step forward: the Netherlands will be the first nation to field the new ammunition. Already qualified by the Bundeswehr, the Rh 40 DM 131 has a maximum range of over 40 km. Moreover, the use of insensitive explosives in this new 155 mm round clearly places it at the forefront of global artillery technology.

Worth around EUR 33 million, the contract encompasses 10,000 artillery shells as well as 67,000 DM 92 modular propelling charges (MTLS), likewise qualified by the Bundeswehr. Delivery will take place through to the end of 2007. The Netherlands is buying this package of artillery rounds and propelling charges as part of its PzH 2000 self-propelled howitzer procurement program (Rheinmetall AG).

Press Release 08.04.2005, from Krauss-Maffei Wegmann

Greece buys 183 main battle tanks LEOPARD 2A4

Greek government representatives in Berlin on August 3, 2005 signed a contract for the purchase of 183 used Leopard 2A4 and 150 Leopard 1A5 main battle tanks (MBTs) from Bundeswehr (German Federal Army) reserves. The deal between the German and Greek governments involves a substantial work package for Krauss-Maffei Wegmann (Munich, Germany).

Krauss-Maffei Wegmann (KMW) will have a share of around USD $185 million in this governmental transaction for repair and technical modification of the Leopard 2A4 MBTs and for supply of special tools. In addition, KMW will provide repair capabilities for Leopard 2A4 MBTs in Greece from 2006 on.

Munich, August 4, 2005.

Kampfpanzer Leopard 2

Leopard 2A6, German Bundeswehr.

| LEOPARD 2A6 MAIN BATTLE TANK - SPECIFICATIONS | |

| Crew | 4 |

| Weight | 62 metric tons |

| Length | 7.7 m |

| Width | 3.7 m |

| Height | 3.0 m |

| Armament | 1 x Rheinmetall 120 mm L55 smoothbore gun |

| 1 x coaxial 7.62 mm machine gun | |

| 1 x 7.62 mm anti-aircraft machine gun | |

| Maximum speed | 72 km/hr |

| Maximum range | 500 km |

| Powerplant | MTU MB 873 multi-fuel, 1500 hp |

| Transmission | Renk HSWL 354 |

| Gunner's sight | Rheinmetall Defence Electronics EMES 15 with thermal channel and laser rangefinder |

| Commander's sight | Rheinmetall Defence Electronics PERI-R17A2 with thermal channel |

MAIN CONTRACTOR

Krauss-Maffei Wegmann GmbH & Co. KG

Krauss-Maffei Wehrtechnik GmbH, the company's defense division,

merged with Wegmann & Co. GmbH, Kassel, in a joint

venture, Krauss-Maffei Wegmann GmbH & Co. KG, Munich

(KMW). The merger was approved by the German anti-trust

authority and became effective on January 1 1999, The defense

division was disincorporated on December 31 1998. KMW is

now a market and technology leader in the field of armored

vehicles and well-positioned to operate successfully in

an environment of growing internationalization of defense

companies and shrinking national defense budgets.

CONTRACTORS

Ametek Rotron - Brushless Motors, Fans and Blowers

AVITRONICS Pty Ltd - Laser Warning Systems for Combat Vehicles

Behr Industrietechnik - Cooling and Air-Conditioning Systems

BEI Precision Systems & Space Division - Optical Encoders, Scanners and Accelerometers

CelsiusTech Vetronics - Fire Control Systems

COMET GmbH - Battlefield Simulation Ammunition

Diehl Remscheid GmbH & Co - Armoured Vehicle Tracks

ERA Technology Ltd - Military Design and Development Consultancy